Gantiel Vensott

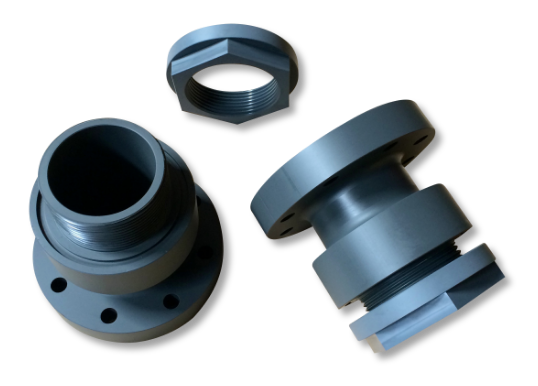

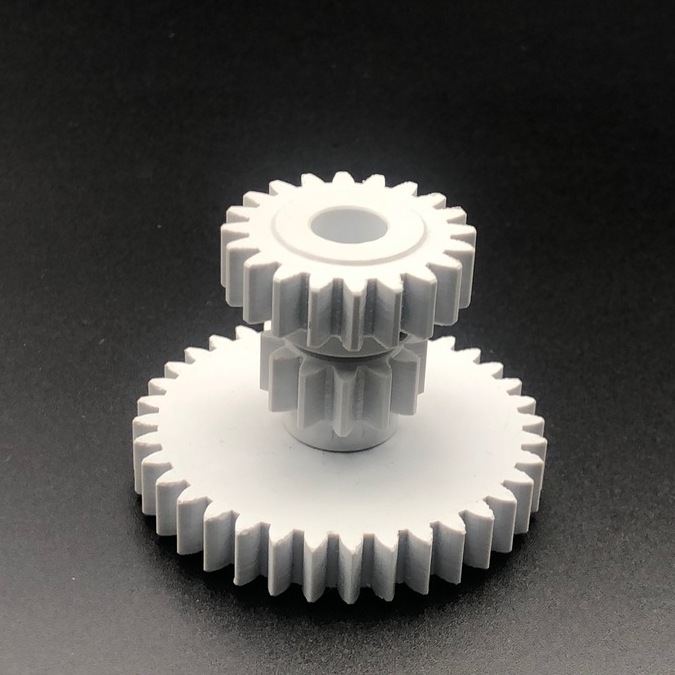

We offer our customers a complete service when manufacturing plastic guarding. We serve and produce components and finished product including gears, wheels, hammers, spokes, tapes, fabrics. Our diverse portfolio of materials can be compounded and manufactured into forms only limited by imagination.

WHAT WE WORK WITH

Materials

The materials available can be formed into sheets, tubes, rolls, belts, tapes, shapes and other forms that may be flexible or rigid, that are capable of enduring temperature extremes whilst remaining intact, resilient and long wearing.

LEARN MORE

HOW WE HELP

Services

Gantiel Vensott’s culture is all about service. We offer specific industry services which benefits our clients including Machining, Installation and Technical Support. We have a very strong network of world class contractors and machinists whose vast range of capabilities and experience allow us to convert an extensive range of plastic shapes into a finished product made to your specifications and best suited to your end application.

LEARN MORE

WHO WE HELP

Industry

We produce and manufacture across diverse industries for specific purposes including:

Electrical Switchboard Manufacturing

Farming and Agricultural Equipment

Food Processing

Transport Industry

Water Treatment

USING OUR PRODUCTS

Applications

Our range of materials and products satisfy an extensive array of applications. The possibilities are limitless.

LEARN MORE